English

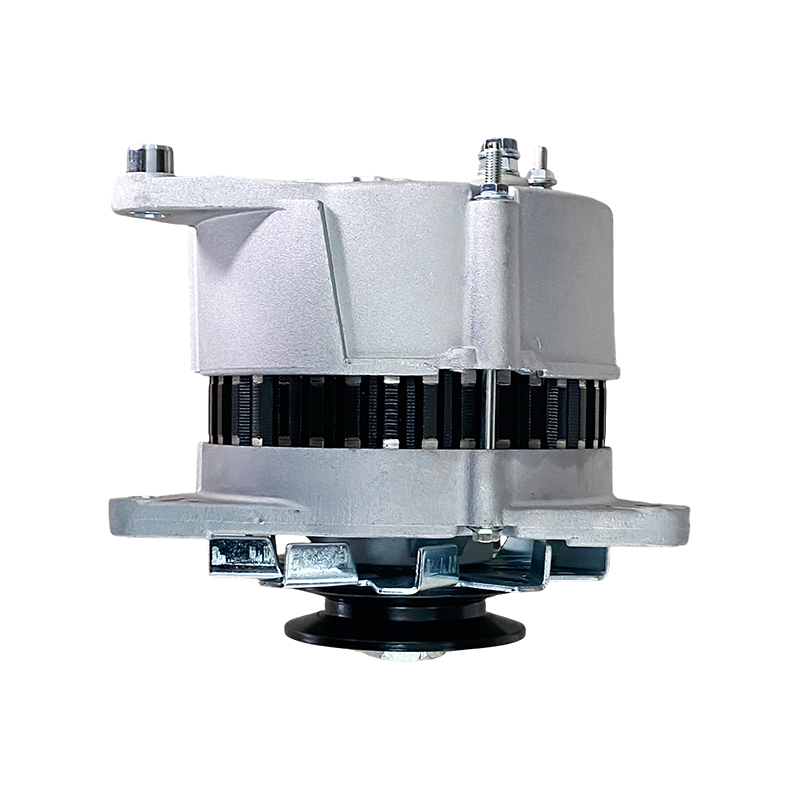

This 12V 55A 1PK Lucas alternator is designed for classic and commercial FORD vehicles, including Capri III, Cargo, ESCORT II-VI, FIESTA I-III, GRANADA, ORION I-II, SIERRA, TAUNUS, TRANSIT, and Mercury Capri models. Engineered for a wide range of 1.0L–2.8L engines, it ensures reliable power delivery for electrical systems in both passenger and light commercial vehicles.

Manufactured using 100% brand-new quality components by WAI, this alternator is built to meet or exceed original factory specifications. It features clockwise rotation, V1 pulley (78mm OD), 1 groove, plug clock at 05:00, plug code 110, and design type IR/EF. Its robust construction offers high durability, excellent resistance to vibration, and stable performance under varying operating conditions.

Compatible with multiple OEM and aftermarket references, including WAI 13107N, LESTER 13107, 14048, 14049, 20227, 22009, BOSCH 0 120 400 902–0 120 489 594, FEMSA ALN12212, ALT12N39, FORD 715F-10300-BB, 74GB-10300-AA, 75AB-10300-LA, 75AB-10300-NA, 75EB-10300-EA, 76BB-10300-DA, 76BB-10300-EB, 76BB-10300-GA, 76BB-10300-GB, D, JCB 333/G6698, LETRIKA AAK1148–AAK4524, MARELLI 054022384010, 054022581010, 054022598010, 063534892520, 943356455010, and VALEO 9AL2688K.

This alternator provides dependable and efficient power support for vintage and commercial FORD and Mercury vehicles, helping maintain optimal electrical system performance and ensuring long-term reliability.

Mounting Dimensions

Specifications

OEM NO.

Applications

| Specifications | MFR | LUCAS |

| Voltage | 12 | |

| Amp. | 55 | |

| Grooves | 1 | |

| Pulley | V1 (78mm OD) | |

| Rotation | CW | |

| Plug Clock | 5:00 | |

| Plug Code | 110 | |

| Design | IR/EF |

| Producer | Number |

| WPS | 13107N |

| LESTER | 13107, 14048, 14049, 20227, 22009 |

| BOSCH | 0 120 400 902, 0 120 400 903, 0 120 400 906, 0 120 488 210, 0 120 489 050, 0 120 489 074, 0 120 489 075, 0 120 489 084, 0 120 489 086, 0 120 489 087, 0 120 489 088, 0 120 489 090, 0 120 489 091, 0 120 489 092, 0 120 489 093, 0 120 489 095, 0 120 489 103, 0 120 489 148, 0 120 489 176, 0 120 489 177, 0 120 489 266, 0 120 489 267, 0 120 489 269, 0 120 489 289, 0 120 489 290, 0 120 489 291, 0 120 489 305, 0 120 489 345, 0 120 489 508, 0 120 489 509, 0 120 489 561, 0 120 489 562, 0 120 489 589, 0 120 489 590, 0 120 489 594, |

| FEMSA | ALN12212, ALT12N39 |

| FORD | 715F-10300-BB, 74GB-10300-AA, 75AB-10300-LA, 75AB-10300-NA, 75EB-10300-EA, 76BB-10300-DA, 76BB-10300-EB, 76BB-10300-GA, 76BB-10300-GB, D, |

| JCB | 333/G6698 |

| LETRIKA (ISKRA) | AAK1148, AAK3590, AAK4135, AAK4139, AAK4513, AAK4520, AAK4522, AAK4523, AAK4524 |

| MARELLI | 054022384010, 054022581010, 054022598010, 063534892520, 943356455010 |

| VALEO | 9AL2688K |

KEEP IN TOUCH

Our factory specializes in producing starters, generators, and spare parts for automobiles, tractors, and internal combustion engines. We possess advanced production and processing technology, complete equipment, and rigorous testing methods. Through years of hard work and entrepreneurship, we have gradually developed into a company of considerable scale and strength. Our "Xiyun" brand has gained considerable influence in the industry, and our products are sold throughout China. Some of our parts are exported to the United States, Canada, Russia, Brazil, and other countries, enjoying widespread popularity and praise from users.

Our factory currently has fixed assets of over 5 million RMB, working capital of over 4 million RMB, covering an area of over 20,000 square meters, with a building area of over 12,000 square meters. We currently produce DC starters and AC generators for construction machinery. Our main equipment includes 2 large hydraulic presses, 5 medium and small hydraulic presses, over 30 machine tools such as lathes, grinders, and milling machines, and over 50 sets of various specialized testing equipment. We have over 60 employees, including 3 engineers, 5 technicians, and 9 full-time technical personnel. Currently, the factory has an annual production capacity of over 150,000 starters, over 200,000 generators, over 150,000 armatures, and over 150,000 electromagnetic switches.

Our factory has a sound organizational structure. The factory has five management departments: quality inspection, technology, production, sales and marketing, and finance; and three workshops: generator assembly, starter assembly, and machining. Various organizational management regulations and training plans are being further improved to ensure high-efficiency and high-quality production.

Our factory passed ISO9000 international quality system certification in December 2000, was rated as an AAA-level credit enterprise in 2001, and passed IATF16949 certification in 2023. Currently, our factory supplies main engine manufacturers including Shanghai Diesel Engine Factory, Nantong Diesel Engine Factory, Guiyang Diesel Engine Factory, Wuxi Power Engineering Co., Ltd., and Tianjin Power Machinery Factory. Our factory will steadfastly implement the principles of "quality first, customer foremost, strict management, and brand creation," providing our customers with superior products through sincere service and excellent quality.

Against the backdrop of global energy transition and industrial upgrading, the generator manufacturing industry is undergoing structural transformation. With the increasing demand for new energy power...

READ MOREAgainst the backdrop of global energy structure transformation and equipment manufacturing upgrades, the generator and its component industry is ushering in a new round of technological innovation and...

READ MOREWith the continuous development of industries such as automobiles, construction machinery, shipbuilding, and power generation equipment, the requirements for the starting performance of power systems ...

READ MORE